Trucking Top 50: Investing in the Present

What do the Top 50 Trucking companies have in common? Seasoned management teams backed up by solid operations—and they’re not afraid to spend on staff and technology to stay on top.

Latest Logistics News

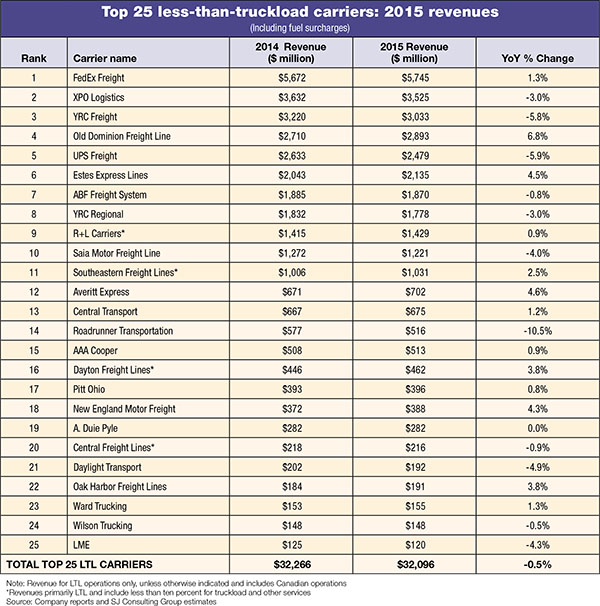

Warehouse/DC Automation & Technology: It’s “go time” for investment 31st Annual Study of Logistics and Transportation Trends Warehouse/DC equipment survey: It’s “go time” for investment Global Logistics/3PL Special Digital Issue 2022 Motor Freight 2022: Pedal to the Metal More Special ReportsThere’s the $65 billion giant UPS, which delivers everything from envelopes to full truckload (TL) with a sizeable less-than-truckload (LTL) unit that ranks fifth on Logistics Management’s (LM) Top 25 LTL list. And there’s the innovative LTL carrier Pitt Ohio (No. 17) that’s rolling out customized solutions to shippers and teaming with other carriers in the Reliance Network to form an efficient long-haul national operation.

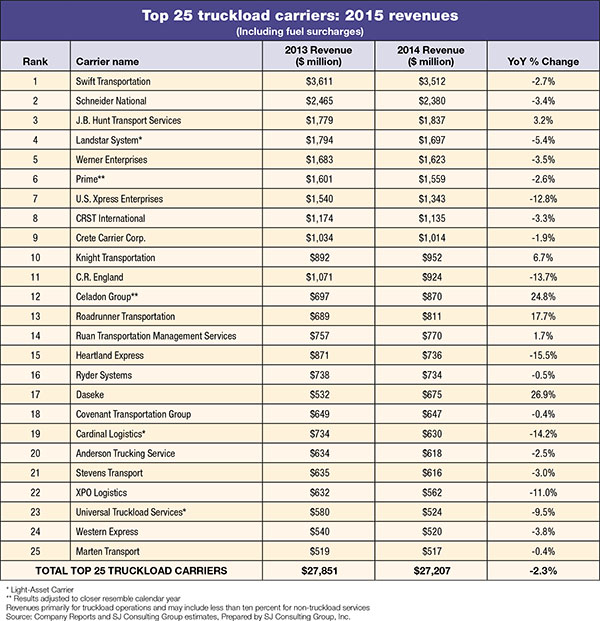

Then there are the privately held carriers such as New England Motor Freight (No. 18 LTL), run by the legendary Myron P. “Mike Shevell, who has more than 60 years’ experience in the industry. Another privately run exemplary company is Green Bay-based Schneider (No. 2 TL). Both NEMF and Schneider enjoy all the access they want to lending markets because of their long history as family-run companies with stable management teams and efficient operations.

Despite all the different shapes and sizes, analysts say that the common thread among these carriers—and all of LM’s annual listing of Top 50 trucking companies—is they have great senior management that operates with a solid vision of their market and customers.

“Having the right people who work together is the key,” says Satish Jindel, principal of trucking analyst firm SJ Consulting, adding that continuity and retention of key people is another vital aspect. In short, most analysts believe that effective trucking management teams must develop discipline within their organization to do good for employees and customers—and not solely to please Wall Street and shareholders. “Those people come and go,” Jindel says. “Your employees and customers stay.”

And it appears that most of the best companies in the market realize just that. “Employee engagement is important to the company,” says James Welch, CEO of YRC Worldwide. “We believe our professional workforce and their experience should give us an advantage as we move forward.”

In line with these goals, eligible Teamsters employees at the YRC Regionals—Holland, Reddway and New Penn—recently received a profit sharing bonus of 1% of their 2015 wages. “From what we can find, this is the first time in the history of our industry that a carrier has paid out a cash profit sharing bonus to its unionized employees,” says Welch.

While pay is obviously important, a clear operating strategy may be even more vital to top trucking companies. Let’s take a look inside the strategies being employed by some of the Top 50 trucking companies and learn what makes them tick in this new era of heightened service expectations and ever-mounting regulation.

Click for high resolution version

Staying on top

As vice chairman and CEO of perennial LTL leader Old Dominion Freight Line (ODFL), David Congdon presides over a multi-modal, $3 billion transportation giant. In fact, ODFL leads the LTL industry with a stunning 83.2 operating ratio (OR) in an era when a 90 OR is considered exceptional.

In the meantime, ODFL is operating profitably, with operating income rising 12.9% last year to $498 million. Last year in the fourth quarter, when most carriers were seeing income erosion due to a soft economic environment and declining fuel surcharges, ODFL set company records for operating income and earnings.

“We won additional market share in the fourth quarter due to increased demand for our services,” Congdon recently told analysts. “This value proposition continues to be critical for both our financial success and our ability to consistently outperform the growth and profitability of our industry.”

ABF Freight System (No. 7 LTL) is the largest operating unit within ArcBest Corp. Now run by president and CEO Judy McReynolds, ArcBest has set out on a deliberate course to lessen its reliance on “asset heavy” units such as ABF in favor of “asset light” unit such as Panther Expedited, ABF Logistics and FleetNet, its fleet maintenance unit.

In the 2015 fourth quarter, these asset light units accounted for 30% of ArcBest revenue. In 2009, unionized LTL carrier ABF captured as much as 93% of its parent company revenue. Based on these figures, it’s becoming clear that there’s a concerted effort to move away from the unionized unit to put more emphasis the union-free businesses.

“Every day we find new ways to solve our customers’ supply chain challenges with the array of services we offer,” says McReynolds. “Our enterprise solutions group works to combine service offerings across ArcBest in a way that simplifies the experience of our customers. This group has been successful in gaining business that we would not have otherwise had.”

But while the push toward asset light moves forward, ArcBest has not forgotten training for its unionized employees. ABF Freight recently placed 23rd among Training magazine’s Training Top 125, a list that ranks excellence in employer-sponsored training and development programs. ABF Freight appeared on the list for the seventh consecutive year.

“Training is firmly integrated into every aspect of our company,” says Tim Thorne, president of ABF Freight. “That’s particularly true of our Quality Process, which relies on continual training and improvement as we strive for error-free service for our customers.”

Click for high resolution version

Challenges ahead

The current freight environment, according to Pitt Ohio (No. 17 LTL) president Chuck Hammel, is “tepid.” Hammel says demand is on par with capacity, but the overall U.S. economy often sends truckers mixed signals on how robust demand actually is. For that reason, Pitt Ohio has diversified away from being strictly a northeast regional carrier and offers a full menu of supply chain solutions—including long-haul LTL and other customized services.

Rick O’Dell, president of Saia (No. 10 LTL), calls the industrial economy “mixed.” Others say demand ebbs and flows from week to week, as if the U.S. economy is unsure of itself.

So how do the best carriers plan for the future with such an opaque economic crystal ball? Let’s examine what they’re doing right now to plan for an uncertain future.

Naturally most trucking executives say that their business is best when there’s a robust economy producing so many goods that freight is filling up their trucks. However, the 2016 U.S. economic forecast is not that good. Mark Rourke, executive vice president and COO of Schneider, says that the current economy “has a 2013 feel” to it. “It’s not robust, but it’s not terrible by any stretch…it’s kind of average,” he adds.

In the truckload sector, the biggest challenge is finding drivers. According to American Trucking Associations estimates, there’s currently a shortage of about 40,000. Noel Perry, senior consultant for FTR Consulting, predicts that figure could go as high as 200,000 in the next decade.

All this is raising the bar for shippers, carriers say. Last year, carriers implored customers to become “shippers of choice”—making themselves more attractive to carriers, improving facilities, and gaining better respect for a truck driver’s time in and out of their facility.

“The shipper community has been incredibly responsive, which is a good thing,” says Rourke.

On top of the driver shortage, there’s the seemingly ever-growing list of regulations, with the next regulatory burden on the industry coming in 2017—when the requirement of electronic logging devices (ELDs) hits the industry. Rourke says that this could potentially be the most disruptive force in the trucking industry since it was deregulated in 1980. Others agree.

YRC’s Welch believes that the ELD requirement “may have a direct impact” on capacity—just how great an impact is under debate.

Estimates from technology experts and those carriers that already have installed the ELD units believe trucking will suffer between a 10% to 15% loss in productivity because capacity will shrink between 7% and 10% when installations are done industry wide.

But because ELDs are projected to eliminate HOS cheating, carriers are concerned that there may be need for additional drivers and equipment. The American Trucking Associations and Truckload Carriers Association lobbied for this rule because they felt the industry was suffering a black eye from “bandit” carriers running over the legal number of hours allowed—11 hours a day, 60 hours in a seven-day period.

“Our goal is to be positioned for the future with an upgraded fleet, more modern and improved technology, and a more engaged workforce that understands that the better they perform the better the company performs—and the better they’ll do financially,” Welch said.

What about rates?

Drivers are scarce and are costing more, and there’s a lid on capacity due to that fact. In the meantime, regulations are tightening, threatening even greater consolidation. So what logical conclusion is there for rates?

Most analysts and carrier executives say that shippers should plan for increases in their base rates in the 3% to 5% range. However, because of the drastic drop in fuel surcharges, overall transport costs may actually fall this year, causing carriers to be cautious in how they approach shippers come negotiation time.

Pricing is a matter of “finding the right balance with finding the right customers with the right mix of freight,” says Rourke. Getting enough customers with sufficient freight density in key lanes is the key to profitability, carrier executives say.

XPO chairman and CEO Brad Jacobs says that carriers “have learned a lot since the last downturn” in 2008. “They’re matching capacity additions to demand, and as a result, pricing is very good and continues to be very good. It’s a tale of two markets—volumes are consistently down and pricing has been consistently up. If I had to pick, I’d choose the latter.”

Jacobs says that shippers always want a fair price, and that’s understandable. “For the most part, shippers understand capacity will tighten up again sooner or later. But they want quality capacity with stable carriers at a reasonable price—this allows them to hedge against eventual tight market later.”

As fuel surcharges come down, Jacobs adds, that has taken pressure off customers’ transportation budgets. Noting that fuel surcharges are way down, Jacobs says many carriers can expect their base rates to rise, but shippers are still getting a bargain oftentimes. “Net pricing is down,” he says.

Pitt Ohio’s Hammel agrees. “With the price of fuel continuing to fall, shippers are paying less for fuel surcharges, so giving carriers increases will still fall in line with their budgets.”

Overall, the trucking industry is rather bullish on 2016. For example, Transport Capital Partners (TCP), which provides advisory services to trucking companies, does an annual survey of truckload executives. At the start of 2015, 79% of survey participants were looking forward to rate increases. At the start of this year, that number fell to 41%—the lowest percentage TCP recorded since 2009.

But even with carriers’ rate expectations tempered, some 41% of those surveyed expected their freight revenue to rise this year. And 61% said that they planned to expand their fleets this year. “Any further tightening caused by a small increase in demand or driver shortages will have a proportionately greater impact on spot and contract rates,” says Richard Mikes, a partner at TCP.

Saia’s O’Dell adds that in the very short term, rates are difficult to predict. “But in the long term, in order to achieve an economic return on capital, rates will increase to compensate for continuing driver wage pressure, benefit costs and the substantial equipment and technology investments required to meet customer expectations.”

The bottom line: The best trucking companies are spending much more to staff their operations and stay on top with technological and other improvements. However, keep in mind that margins at even the best companies are so thin that they have no choice but to try and pass these costs on to their customers.

Article Topics

Special Reports News & Resources

Warehouse/DC Automation & Technology: It’s “go time” for investment 31st Annual Study of Logistics and Transportation Trends Warehouse/DC equipment survey: It’s “go time” for investment Global Logistics/3PL Special Digital Issue 2022 Motor Freight 2022: Pedal to the Metal Top 50 Trucking Companies: The strong get stronger 2019 Top 50 Trucking Companies: Working to Stay on Top More Special ReportsLatest in Logistics

Under-21 driver pilot program a bust with fleets as FMCSA seeks changes Diesel back over $4 a gallon; Mideast tensions, other worries cited Four U.S. railroads file challenges against FRA’s two-person crew mandate, says report XPO opens up three new services acquired through auction of Yellow’s properties and assets FTR’s Trucking Conditions Index weakens, due to fuel price gains U.S. rail carload and intermodal volumes are mixed, for week ending April 6, reports AAR LM Podcast Series: Examining the freight railroad and intermodal markets with Tony Hatch More LogisticsSubscribe to Logistics Management Magazine

Find out what the world's most innovative companies are doing to improve productivity in their plants and distribution centers.

Start your FREE subscription today.

April 2023 Logistics Management

Latest Resources