Sustainable packaging is ready to make its mark

Whether it’s about cost or environmental savings, sustainability is taking on greater importance in packaging—and that will impact supply chains from Amazon to automotive.

Slowly. Ever so slowly, the sustainability of packaging is becoming recognized as good business. However, that rate of acceptability appears ready to accelerate. Rapidly. Maybe very rapidly. It’s rare that such a shift can be pinned down to a specific day. However, this time it can: Aug. 1, 2019.

That’s the day Amazon set for its merchants to make their packaging more environmentally friendly to specific standards. And while environmentally friendly is a broad term, in this case it means make shipping packages “optimized for Amazon fulfillment,” say the company’s guidelines. Failure to comply with the standards results in packaging surcharges for each package shipped—and it’s a powerful motivator.

“Amazon’s mission is to optimize the overall customer experience by collaborating with manufacturers worldwide to invent sustainable packaging that delights customers, eliminates waste

and ensures products arrive intact and undamaged,” the guidelines say.

It even applies to bags of dog food. This is a big deal. After all, if Amazon can’t get the sustainable packaging party started, who can? Just as important, Amazon’s objectives exactly mirror those of suppliers of sustainable industrial packaging interviewed for this article. And that’s true whether the packaging is one-time use corrugated boxes or reusable plastic containers.

In fact, reusability is anything but new to the auto industry, says Mark Ward, business development manager at SSI Schaefer’s Systems Package Division. “Despite its long history here, automotive is always looking for ways to control packaging costs and protect parts in transit. And their answer is reusable packaging for every shipment,” he says.

Or as Ken Beckerman, CEO of Flexcon, says, “people love green and if there’s green in their wallet it’s even better.”

The value of sustainability

Actually, there’s quite a bit of money riding on sustainable industrial packaging, says Hanko Kiessner, CEO of Packsize. To begin, Kiessner and others say the average box is 40% too large for its contents. That’s impressive in the wrong way. If excess volume were reduced, says Kiessner, it would eliminate 24 million of the 60 million truckloads of product shipped annually in the United States.

That would save 1.75 billion gallons of diesel, preventing 17 billion kilograms of carbon dioxide from entering the atmosphere. And even if someone wants to argue with those numbers, the order of magnitude of the consequences of inefficient packaging is impressive—again, in the wrong way.

There’s also the matter of DIM weight, or dimensional weight. Carriers such as UPS, USPS, FedEx and others determine DIM weight by multiplying a package’s length, width and height then dividing that by a number called a volumetric divisor. The resulting number is then compared to the package’s actual weight and the higher number is used to determine the shipping costs of the package.

The long and the short of DIM weight is that the smaller the package, the less costly it typically is to ship. Once again, sustainability has real value in the supply chain. Now we’re all familiar with the plastics vs. paper/corrugated/biodegradable back-and-forth discussions about sustainability. And too often, people see this as an either/or choice which only rarely is in favor of plastics.

However, it’s not that simple with industrial packaging. After all, there are good reasons that reusable plastic totes and containers dominate in certain supply chains. Plastic reusables are a significant contributor to packaging sustainability, explains Aman Sangha, product manager and sustainability lead at ORBIS. He advocates a life-cycle analysis to compare the viability of single-use or reusable packaging to maximize sustainability.

“It provides an unbiased comparison of materials for a package in the context of the application, including disposal or recycling at the end of its useful life,” Sangha explains. The outcome is a factbased, accurate environmental report that justifies use of a specific material for a particular package and use, he says.

Circularity is the word used by Dan Healey, sustainability director at Sealed Air. Circularity, he says, describes the closed-loop life-cycle of the materials and the package itself. Healey says it starts with how the materials are made and converted into a product (tote or box, for instance). It includes use of the product for as long as possible until it reaches the end of its useful life and is recycled.

Several factors are at play here to determine the efficiency of circularity. They range from the materials themselves to the amount used and their cost. Materials may be recyclable or even part of a recycled materials mix for the next generation of packaging.

Healey points out that Sealed Air has pledged to make its packaging solutions 100% recyclable or reusable by 2025. In addition, the company has set a target to use 50% average recycled content in all of its packages of which 60% will be post-consumer recycled content.

Circularity, indeed. Meanwhile, CHEP has created Zero Waste World, a program to create smarter and more sustainable supply chains using the company’s pallet pools. The idea is to, wherever possible, eliminate waste, empty transport miles and supply chain inefficiencies. A forerunner of Zero Waste World, says Laura Nador, president of CHEP North America, is California’s Giant Berry Farms.

During the past 17 years, it has used pooled, reusable pallets to remove 1.2 million pounds of carbon emissions and avoid 1.6 million pounds of solid waste in landfills. All of these factors bring great value to sustainability in industrial packaging. And that, in turn, is generating many new advances.

What’s new in boxes, dunnage

As might be expected, there is no shortage of new ideas in sustainable industrial packaging. Let’s visit e-commerce and other parcel shipments to start. Package size is a giant focus here. Oversized boxes have long used void fill, primarily plastic or paper, to fill out the excess space and protect the contents from damage in transit. Now the push is to right size the boxes without wasted space.

On the box front, new automated boxforming machines offer great right-sizing flexibility. Players here include Packsize, Westrock’s Box On Demand, Sealed Air

and RanPak. Generally, these automated machines do not build boxes precisely to size. Instead, they cut down one of the box dimensions to size, leaving the other two dimensions standard, eliminating much of the previous void.

Other systems cut down the box in more than one dimension. Meanwhile, Sealed Air has developed two recyclable packaging solutions to protect two quite different products inside right-sized boxes. One is called Korrvu, a protective packaging solution specifically designed for electronics. The packaging holds a product in the center of the box, protecting it from shock and vibration. It completely eliminates the need for void fill or cushioning materials and is curbside recyclable.

The other is TempGuard, an insulated recyclable paper pad that protects temperature sensitive and perishable goods for 24 to 48 hours. It can be used to ship meal kits and other food items. Even dunnage, which is not entirely going away anytime soon, is getting some sustainability attention.

EcoPure is a plant-based polyethylene foam produced from sugar cane. The supplier, Sealed Air, says the protective foam has the potential to yield a negative carbon footprint value. Cultivation of sugar cane uses carbon dioxide and releases oxygen, reducing the carbon footprint. EcoPure protects products as diverse as consumer electronics and medical equipment.

New reusable containers

In the auto industry and elsewhere, it’s common to ship product in containers that collapse for the return trip, saving space in the trailer and eliminating wasted trips for the trailer. Flexcon recently introduced one for

closed-loop systems. These heavy-duty plastic corrugated containers save 75% of the original space when collapsed. That allows consolidation of multiple original loads of containers on the return trip, resulting in significant fuel savings on that transportation leg.

SSI Schaefer offers its CF line of collapsible containers. However, that line is now being significantly enhanced with a new line of patented collapsibles. Unlike others, these containers collapse with the flexible textile dunnage in it, allowing four times the number of containers on the trailer return trip as on the outbound route. That saves considerable fuel on return trailer trips.

A new reusable from ORBIS is the Multitank storage and transport container with 400-liter capacity. Its conical design is stackable when full and nestable when empty, reducing space requirements on return trips by 75%. All of that said, tracking reusables can be a challenge. To help with that, ORBIS has created its RPM (reusable packaging management) platform to track reusable packaging. RPM’s backbone is a proprietary software system called SmartTrak.

It tracks, retrieves and redistributes reusable packaging assets, providing packaging asset visibility across the supply chain. Orbis RPM has more than 40 service centers in North America. It recently opened two service centers to sort, de-label, count and return reusable bulk bins for a leading automotive supplier in Canada. By tacking containers in use, RPM also offers the auto supplier visibility into its inventory of bins, helping the company to replace or add to the inventory as business dictates.

No doubt that sustainability has buzz in the supply chain. In fact, sustainable industrial packaging is clearly becoming increasingly important to cost containment while reducing environmental impact.

Companies mentioned in this article

Sustainable Products and Accessories

PitMaster V Dock Face Sealing System

PitMaster V Dock Face Sealing System

Dock sealing system increases safety and reduces energy costs.

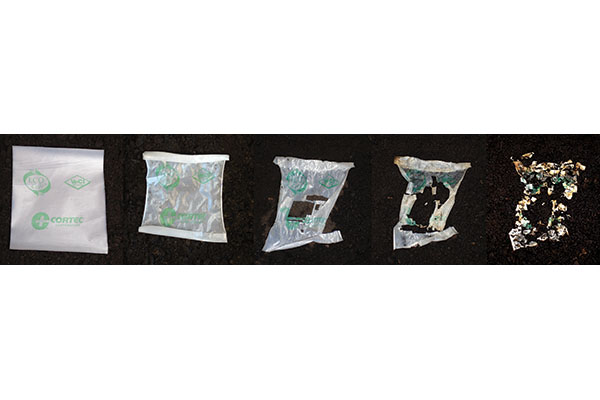

Eco-Corr® Biodegradable VpCI® Film

Eco-Corr® Biodegradable VpCI® Film

Biodegradable anticorrosion film.

Xtreme Force industrial motive power batteries

Xtreme Force industrial motive power batteries

Battery technology uses less energy.

Smart Motor for mains operation

Smart Motor for mains operation

A single motor for many applications.

Pit Stop Line of Forklift Tires

Pit Stop Line of Forklift Tires

Forklift tire indicates wear for greater lifespan, sustainability.

Corrugated Packaging

Corrugated Packaging

How Corrugated Boxes Support Omnichannel Sustainability

Article Topics

Latest in Logistics

LM Podcast Series: Assessing the freight transportation and logistics markets with Tom Nightingale, AFS Logistics Investor expectations continue to influence supply chain decision-making The Next Big Steps in Supply Chain Digitalization Under-21 driver pilot program a bust with fleets as FMCSA seeks changes Diesel back over $4 a gallon; Mideast tensions, other worries cited Four U.S. railroads file challenges against FRA’s two-person crew mandate, says report XPO opens up three new services acquired through auction of Yellow’s properties and assets More LogisticsSubscribe to Logistics Management Magazine

Find out what the world's most innovative companies are doing to improve productivity in their plants and distribution centers.

Start your FREE subscription today.

April 2023 Logistics Management

Latest Resources