Goya Foods’ secret ingredient: Lift trucks

The leader in Hispanic food and beverage products puts a variety of lift trucks and racks to work in its distribution centers, including a special Goya spec truck.

There’s something just a little bit different about the lift truck putting away a pallet in the six-deep, drive-in pallet rack in Goya Foods Inc.’s 643,000-square-foot distribution center in Jersey City, N.J. Goya worked closely with its long-time lift truck distributor (Yale and Barclay Brand Ferdon) to modify the guard, the fender over the front wheels, and the wheels themselves to create a Goya specification that works with all of the racking in the facility and optimizes the work flow. The Goya spec is now standard for other Goya facilities.

“When we moved into this facility about four years ago, we were using taller rack than we had used in our older, smaller facilities,” explains John Quinones, director of operations. “The overhead guard on the standard lift truck we were using wouldn’t allow us to drive into the rack, so we had to use two different vehicles for putaway and retrieval. One staged a pallet and another would drive into the rack. By modifying the truck to create a Goya standard, we were able to eliminate that extra touch.”

Getting the most out of its fleet of lift trucks is the secret ingredient to efficient operations across Goya’s network of DCs, where lift trucks do the heavy lifting. The equipment portfolio includes sit down trucks, standup reach trucks, two types of very narrow aisle (VNA) trucks (Yale and Landoll Bendi), tuggers and trucks with lower masts for slip sheet handling. Goya is running a fleet of some 500 Yale trucks across its DC network. Quinones adds that Goya is considering automatic guided vehicles or automatic lift trucks to automate routine and predictable travel routes in the future. But for now, this is a conventional facility, one that makes the most of a variety of rack and floor storage solutions, and uses sophisticated planning software, warehouse management system (WMS)-enabled task interleaving and voice-directed picking to optimize inventory and the work flow.

“We have looked at automation in our distribution centers since our manufacturing is highly automated,” says executive vice president Peter Unanue, whose family founded the business more than 80 years ago. “However, some of our packaging isn’t conveyable, and we require a lot of sortation to load our trucks in the right order for their route stops. Making the most of lift trucks and tuggers is more efficient and cost-effective than automation.” Unanue points out Goya has a 99% fill rate, which he attributes to the supply chain software that manages demand planning, inventory management and picking.

Leading a food category niche

With more than $1 billion in annual sales, privately held Goya Foods is the largest Hispanic-owned food company in the United States and the premier source for authentic Latin cuisine. The company provides consumers with more than 2,500 high-quality and affordable food products from the Caribbean, Mexico, Spain, Central and South America.

Goya was founded in New York City in 1936 by Don Prudencio Unanue and his wife Carolina, immigrants from Spain by way of Puerto Rico, who “were trying to provide a living for their family during the Depression,” says Peter Unanue. The company’s beginnings were a small storefront on Duane Street in Lower Manhattan, where they imported and sold authentic Spanish products such as olives, olive oil and sardines to New York’s growing Hispanic community. The company name was a bit of serendipity. “A case of sardines came in with the word Goya on it,” Unanue says. “Don Prudencio liked the sound of it and bought the rights to the name for a dollar.”

Goya moved its headquarters from New York to Secaucus, N.J., in 1974. Over the decades, the product line expanded to include representations from Spain, the Caribbean, Mexico and Central and South America. In total, Goya now boasts 26 manufacturing and distribution facilities, throughout the United States, Puerto Rico, the Dominican Republic and Spain, including 14 domestic DCs, and it employs more than 4,000 workers worldwide. In areas where it doesn’t have a physical presence, it works with third-party distributors.

Warehousing has been part of Goya’s distribution strategy from the beginning. “A lot of CPG companies of our size ship to their customers’ warehouses,” says Unanue. “We deliver straight to our customers’ stores, which range from big box retailers to neighborhood bodegas. When one of our salesmen visit a store, they place an order on their handhelds, and we process them overnight for next-day delivery.” Like the wine and spirits industry, Goya’s drivers make between 15 and 30 route stops per day. By going direct to the stores, Unanue adds, Goya can get the right product mix in each neighborhood, which can vary from one neighborhood to another.

“Our largest volume is still the New York and New Jersey area where we were founded,” Unanue says. “Depending on seasonality, we move between 40,000 and 90,000 cases a night from the Jersey City facility.”

Designing for growth

In 2005, Goya launched a 10-year strategic plan and invested $500 million in a global expansion, designed to reach new consumers and strengthen the Goya brand worldwide. From 2014 to 2016, Goya opened five new state-of-the-art manufacturing and distribution centers in Texas, California, Georgia and New Jersey to meet consumer demands for Goya products.

At 643,000 square feet, the Jersey City facility is the largest of the DCs and the largest investment the company has made in its network. It was built in 2014 to consolidate operations from two smaller distribution centers in Secaucus and Bethpage, N.Y. “We were bursting at the seams in Secaucus and renting space for the products we couldn’t fit in the building,” says Unanue. “As a private company, we can invest for the future, and we designed this building to sustain 20 or more years of growth.”

_recut.jpg)

Designing for growth began with a more efficient use of space than in previous buildings. Ceiling heights were expanded from 24 to 42 feet clear. Instead of storing pallets five high, they are stored six pallets high and up to nine pallets high in some areas. Goya is also using a variety of storage methodologies, including floor storage, single-deep pallet rack, push-back rack, six-deep, drive-in rack and a section for very narrow aisle (VNA) storage. Using rack that can store more than one pallet deep improved the work flow and productivity, according to Unanue. “We were able to take lift trucks out of the high traffic areas and create a safer work environment because we now pick from the front but replenish from the back of the rack.”

New storage methodologies also enabled more storage strategies. “One of the things we look at is stackability,” Quinones says. “If we have products that are structurally sound, like canned beans, we look at floor storage. We put slow moving items or items with only a few pallets in the VNA. If we get a delivery with say five pallets of an item, we might put that in single-deep rack and have five pick faces. We have a lot of options based on product type and movement.”

Goya was already using a warehouse management system and voice-directed picking but added task interleaving in the new building. The warehouse is currently in the process of implementing “opportunistic substitution,” or crossdocking, that enables a receiver to take product for which there is an order directly from receiving to shipping.

The Goya spec

In a conventional facility where picks are primarily full case or full pallet, lift trucks and tuggers are central to moving product. The company worked with its lift truck distributor to bring in a fleet of trucks for each of the different areas and processes. Those included tuggers and carts for picking; 3,500-pound capacity laser-guided turret trucks in the VNA area; standup reach trucks and standard sit-down riders. There are also trucks with a freezer package to work in a cold storage area. Finally, Goya added articulated lift trucks (Bendi) that have the flexibility to be used in the VNA area and other areas in the facility as well. “The turret trucks work well in the VNA area, but the articulated lift trucks allow us to also use the same truck to put away in the VNA and also replenish a pallet in the pick area,” says Quinones. “Otherwise, we’d have to utilize a staging area and an extra touch.”

Minimizing touches and accommodating the higher ceilings of the new facility were catalysts for the development of the Goya spec truck, which is now standard across Goya distribution centers with drive-in racks. “When we installed the drive-in rack, the overhead guard would not allow the standard trucks we were using to drive into the rack,” Quinones says. “We modified the overhead guard with a curvature. It still gives us the protection we need, as well as the right dimensions to avoid hitting the rack.” Other modifications were made to the wheels, such as removing a fender of the front wheels. The truck also has larger tires than a standard sit-down truck.

Further modifications were made as the facility evolved, and the height of the drive-in racks was extended from five pallets to six pallets high. Most of the original equipment in the building was not capable of reaching that height. “Often, an operator would pick up a pallet in receiving and take it to a designated drop zone, where one of the lift trucks that could reach that high would pick it up and put it away,” Quinones says. Similarly, a truck might retrieve a pallet from the sixth level and take it to the drop zone, where another truck would pick it up. “Once we developed the Goya Spec truck, we began to replace our other equipment so we had one truck that could do it all, and eliminate that step,” Quinones says.

Keep them running

While many operations are choosing to lease their lift trucks and outsource maintenance, Goya for the most part purchases its fleet, manages most of its parts inventory and keeps a crew of skilled lift truck technicians on the payroll. “We may lease equipment that typically doesn’t last long, like pallet jacks,” says Unanue. “But we have certified mechanics onsite to do the day-to-day repairs and buying the trucks just works for us.”

Unanue and Quinones point out that some trucks in the fleet are 20 years old and still in good working condition thanks to the Goya maintenance program. Similarly, some technicians have been on the job for more than 20 years—as long as some of the trucks. With that kind of longevity, purchasing makes more economic sense. And, if they do run into an issue beyond the scope of the on-site shop and team, they bring in their distributor to do the repair.

When it comes to parts management, Goya’s distributor provides vendor-managed inventory for some items, such as switches, while Goya owns the inventory of items used in day-to-day maintenance, such as wheels, rims, hoses, fluids and clamps.

Looking back, Quinones credits the success of the equipment being used at the new facility to the 30-year relationship Goya has had with its distributor. “At one point after the Jersey City building was live, we wanted to add a standup reach truck we have in a racking area,” he notes. “They were here for several weeks studying how we utilize this truck. One of the things they found was that the outriggers were hitting the base of the rack and came up with a way of modifying that truck for us. Because of the height of our rack, they also recommended that we install a laser positioning system and a camera to aid the operator while storing and retrieving pallets. The relationship has been about understanding each other’s needs.”

View Pallet Trucks Products and Accessories

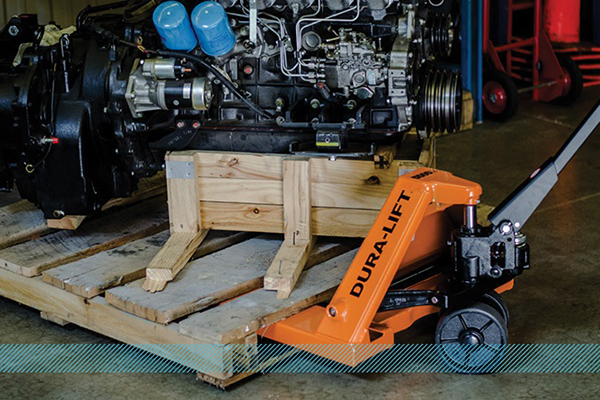

Dura-Lift hand pallet truck

Dura-Lift hand pallet truck

Transport loads up to 5,500 pounds.

PSL Series Skid Lifter

PSL Series Skid Lifter

Powered, manual skid lifter pallet trucks.

Blue Label pallet trucks

Blue Label pallet trucks

Control pallet truck’s operation with lever.

PW 3500 Series walkie pallet truck

PW 3500 Series walkie pallet truck

Pallet truck built for tough environments.

Combi-PPT powered pallet truck

Combi-PPT powered pallet truck

Steer pallet truck from the side for safety.

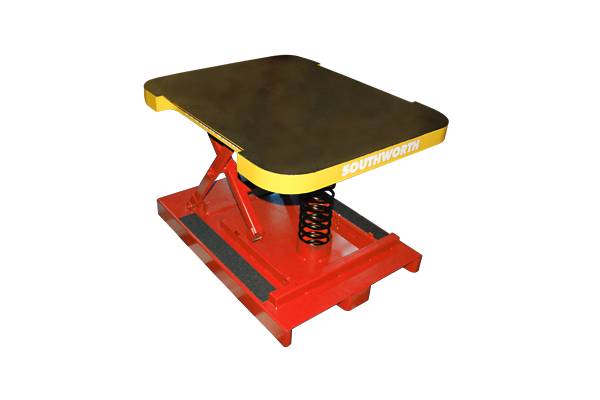

PalletPal walkie mobile leveler

PalletPal walkie mobile leveler

Attachment improves order picking ergonomics.

Article Topics

Latest in Logistics

Cass Freight Index points to annual shipments and expenditures declines ALAN opens up its nominations for 2024 Humanitarian Logistics Awards U.S.-bound import growth remains intact in April, reports Descartes Looking at a reshoring history lesson NTSB: Ship lost power twice before slamming into Baltimore bridge, closing port ISM May Semiannual Report points to growth in 2024, at a reduced rate April retail sales are mixed, reports Commerce and NRF More LogisticsAbout the Author

Subscribe to Logistics Management Magazine

Find out what the world's most innovative companies are doing to improve productivity in their plants and distribution centers.

Start your FREE subscription today.

May 2024 Logistics Management

Latest Resources