Supply Chain Outlook: Preparing for what’s next

Event featured an impressive lineup of keynote and session speakers who hit on all of the topics that are driving supply chain growth right now.

With all eyes on supply chains right now, organizations are investing in more automation, adopting more technology and taking other steps to make sure these critical global networks remain resilient, agile and productive. Every year, the editors of Logistics Management and Supply Chain Management Review unwrap the biggest trends, challenges and opportunities taking place in the modern supply chain and shine a spotlight on them at the Supply Chain Outlook Virtual Summit. An impressive list of keynote speakers and presenters took center stage at the Summit, which covered important topics like generative artificial intelligence, warehouse robotics, supply chain management software and the results of the 33rd Annual Study of Logistics and Transportation Trends. Read on for a summary of each session and then register to experience this year’s Virtual Summit on-demand for yourself.

Session 1: Transportation

33rd Annual Study of Logistics and Transportation Trends: Navigating a shallow pool of resources Logistics operations are facing a human capital crisis that poses a threat to both performance and competitiveness. In this presentation, Christopher A. Boone, Ph.D., assistant professor at Mississippi State University; Karl B. Manrodt, Ph.D., professor at Georgia College and State University; Jason Shin, Ph.D., assistant professor, Mississippi State University; and SMC3’s manager of education programs Joseph Tillman review the results of the Annual Study of Logistics and Transportation Trends. The team of supply chain experts also explore how logistics organizations can compete for talent in an increasingly limited talent pool and how shippers are working to differentiate in an increasingly dynamic business environment. Part I of the presentation focuses on the continuing labor issues confronting logistics and supply chain operations, while Part II identifies and investigates key strategic and technological trends and explores the historical measures of the survey. Manrodt kicks off the session by discussing cost strategy, and how fewer and fewer companies are choosing to compete on cost alone—2.68% in 2023 versus 15.4% in 2016. “That number is continuing to decline,” he says. Tillman adds that the shift in supplier-customer relationships in logistics and a move away from “transaction- based” strategies and over to more “relation-based” approaches. Asked what they perceive to be the biggest challenge going into 2024, respondents were “pretty loud and clear” about their labor concerns, according to Boone. “Talent will continue to be a major issue that all industries are going to face,” he points out. “When you think about how dependent logistics and transportation are on labor, we believe this is a topic that warrants not just continued conversation but probably some added conversation on what companies can do about it.”

Session 2: Software

SCM Software: Essential to the success of the modern operation Companies know that technology helps strengthen their supply chain and provides an improved customer experience to better compete in an e-commerce-driven world. Essential to the efficiency and productivity of modern logistics and supply chain operations, supply chain management (SCM) software stands as the true workforce of the modern supply chain. This session features Howard Turner, director, supply chain execution systems at St. Onge Company, who explores the critical role that SCM continues to play in the smooth-running supply chain. For example, transportation management systems (TMS) are helping logistics and supply chain managers who need to move freight from point A to point B quickly, affordably and efficiently. Turner also talks about the operating framework that has to be in place for systems that support transportation operations including proper utilization of the software itself. Next, he discusses the important distinction between TMS and fleet management systems. “TMS is a catchphrase, to broadly describe transportation software, but there are important distinctions between these two critically important systems,” says Turner, who sees too many transportation management projects fail “due to a hesitancy to put in place the proper organization and the right team to use the software.” Turner’s key takeaways were: 1) ensuring that you have the proper organizational structure in place; and 2) selecting the correct transportation software system, whether that’s done in-house or you partner with a third-party logistics (3PL) provider. “At the end of the day,” Turner says, “an effectively managed transportation services organization is absolutely critical to realizing the full benefits of [SCM] software.”

Session 3: Software/AI

Generative AI and its impact on logistics and supply chain Artificial intelligence (AI) continues to take giant leaps forward, and just as supply chain businesses have become more comfortable with using it, here comes generative AI—basically, AI on steroids. What makes generative AI different is how it can learn the underlying patterns and relationships within the data—then, it leverages that knowledge to generate new, original outputs. Nathanael Powrie, managing director, data analytics at SGS Maine Pointe, tackles the subject of generative AI’s use in logistics and supply chain in this insightful session. He dives into generative AI and its transformative potential for supply chains. “We’ve witnessed the rise of traditional AI, the technology that has fundamentally changed the way we’ve approached supply chain management,” he says. Unlike traditional AI, generative AI doesn’t just optimize—it also generates new content strategies and solutions. “This form of AI analyzes patterns and data to inform decisions, enhancing our ability to predict and act upon known variables,” he continues. “It’s been the backbone of automation, enabling us to streamline operations and make data driven decisions with remarkable efficiency.” Powrie also discusses companies’ “cautious” approach to generative AI, but sees good future potential for this advanced technology in logistics, supply chain and transportation applications. “The potential of gen AI to revolutionize every aspect of the supply chain is immense,” he explains. “From automating mundane tasks to crafting sophisticated strategies, it promises a level of efficiency and insight unprecedented to our history at this time.”

Session 4: Warehouse/DC Automation & Operations

2023 Warehouse/DC Operations Survey: Managing on shaky ground Every year, Peerless Media’s research team conducts the Warehouse & DC Operations Survey to give the market an updated snapshot of current trends in warehouse and DC management. The team reports that the warehouse and DC/fulfillment operations environment is still one of concern and uncertainty as a result of the shaky economy, tightening labor market, extended lead times, and rising equipment costs. In this session, Don Derewecki, senior consultant at St. Onge Co., and Norm Saenz, Jr., partner and managing director at the St. Onge Co., walk attendees through the results of the survey and also discuss the best practices being deployed by warehouses and DCs nationwide. Saenz says that labor woes continue to top the list of challenges that warehouse operators are dealing with right now. He says both finding and retaining good employees—and in the numbers needed to handle all of the order volumes and operational growth companies are experiencing—is becoming more difficult than ever. There’s also a big focus on using more automation for storage, fulfillment and shipping and receiving. Derewecki talks about the increased use of vertical modules and the significant uptick in the use of robotic articulating arms or “manipulators” and automated putwalls in the warehouse setting. Both consultants agree that more automation will make its way into fulfillment centers in the coming years, with the ongoing labor shortage expected to be a major driver of that trend.

Session 5: Third-party Logistics

3PL/Shipper Partnerships: Getting it right requires new ways of thinking Historically, shippers have relied on 3PLs to manage asset-based activities like transportation and warehousing. As those relationships have expanded over the past few years—and as the logistics and transportation environment becomes increasingly complex—it has necessitated a new way of aligning, partnering and working together. This session features Mike Reiss, managing director of supply chain at EY, and Jim Morton, managing director for supply chain and operations with EY Consulting. They explore the increase in service requirements from both the business partner and consumer perspective. “Customers continue to push for more visibility and delivery customization, so [what’s happening] with service requirements probably won’t ever slow down,” Reiss explains. He also discusses the need for better asset balancing, and says companies should be asking themselves: “What assets should I own and which ones should I buy versus borrow?” Reiss explains how, while there are so many great opportunities to implement new technologies, careful thought needs to go into figuring out which of those are right for your business. Reiss also talks to the audience about environment, social and governance (ESG) and the role it’s playing in today’s supply chains. He also covers the role that 3PLs play in sustainability. “Many of the companies we work with have set corporate goals for carbon neutrality,” he explains. “Supply chain is a big part of achieving these goals, and this trickles right down to your logistics operations and the 3PLs you [work with].”

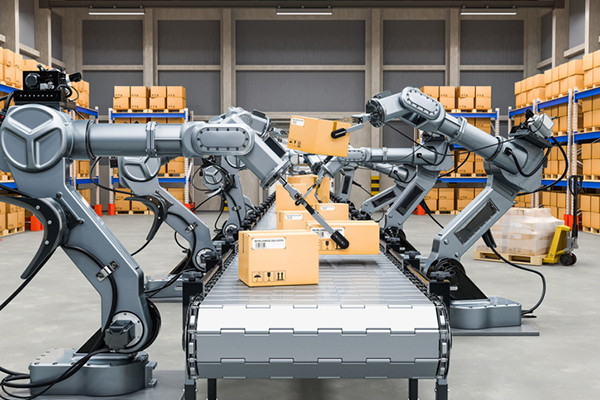

Session 6: Robotics

How do we get all the robots to work together? Ongoing worker shortages, growth of e-commerce, pressure to do more with less and advancements in warehouse robotics over the last couple years are all driving more companies to use robots in their fulfillment operations. By 2028, Gartner predicts that 75% of large enterprises will adopt some form of intralogistics smart robots—robots that orchestrate and perform work within the four walls of a site and can be mobile or stationary, operating autonomously or collaboratively with humans or other robots. In this session, Dwight Klappich, research vice president at Gartner, Inc., takes attendees back 20+ years to a time when the Roomba vacuum was first introduced to the market. Downright revolutionary at the time, Roombas can now be found in many homes—yet, the market didn’t even exist before 2002. Expect the same from the robotics space, which 20+ years from now will probably be fairly routine and mundane, and not nearly as revolutionary as it seems right now. “We believe that within the next three to five years, 75% of companies will have at least one type of robot,” Klappich predicts. “And, around 25% to 40% of those robots will have already be part of a heterogeneous fleet of robots.” Heterogeneous robot fleets are groups of robots in which different types of robots work together to perform tasks. Their popularity is being driven by the fact that once companies successfully integrate a robot into their facilities, they then start looking for places where the next robot can be implemented. “That’s going to result in a lot of companies having heterogeneous fleets of robots,” says Klappich, who hints that there are already numerous use cases underway in the warehousing space and that “companies are moving forward” with these efforts. “There’s a lot of activity taking place and the [heterogenous robotics] solution is only going to get deeper and richer over the next few years,” says Klappich, “and mainly because there is no one robotics vendor that does everything.”

Article Topics

Virtual Summit News & Resources

Supply Chain Outlook: Preparing for what’s next Virtual Summit 2022 Recap: Enabling the workforce of the future 2022 Viewpoints: Think, plan, act 2022 Virtual Summit: Enabling the workforce of the future 2021 Virtual Summit Recap: Develop a game plan for the future 2021 Virtual Summit: Developing a game plan for the future Modern Materials Handling’s 2021 Virtual Summit kicks off July 29 More Virtual SummitLatest in Logistics

Understanding the FTC’s ban on noncompetes UPS rolls out fuel surcharge increases U.S. rail carload and intermodal volumes, for week of April 20, are mixed, reports AAR Baltimore suing ship that crashed into bridge, closing port, costing jobs Intermodal growth volume remains intact in March, reports IANA Descartes announces acquisition of Dublin, Ireland-based Aerospace Software Developments Amid ongoing unexpected events, supply chains continue to readjust and adapt More LogisticsAbout the Author

Subscribe to Logistics Management Magazine

Find out what the world's most innovative companies are doing to improve productivity in their plants and distribution centers.

Start your FREE subscription today.

April 2023 Logistics Management

Latest Resources