FORTPRO partners to optimize space, grow revenue

After experiencing substantial growth in its e-commerce business, master distributor FORTPRO USA/World Truck Parts LLC called on a third party to help it get more out of its existing warehouse space, improve fulfillment throughput, and increase revenues.

Aworldwide leader in the research, development and distribution of a broad range of truck and trailer parts, Miami-based FORTPRO USA/World Truck Parts LLC makes high-quality air brake components, electrical components, engine parts, air compressor parts and other products. Founded in 2006, the master distributor maintains parts distribution warehouses in Miami and Houston.

With a robust domestic and export business, FORTPRO is a master distributor that relies heavily on less-than-truckload (LTL) freight brokers. However, the company has experienced tremendous growth in its e-commerce business over the last three years. “We’ve been expanding our e-commerce business year-over-year,” says Marlon Romero, export manager. “We expect to keep growing at a steady pace.”

As FORTPRO’s e-commerce business expanded, the company needed help managing the subsequent increase in parcel package shipments. It was outgrowing its Miami warehouse and needed help improving the efficiency of its facility in a market where adding new physical space is extremely expensive.

“We were in growth mode in 2021,” says Romero. “All of the aisles of our warehouse were blocked.” For help solving this and other logistics challenges, the company called on UPS Customer Solutions, a third-party provider of a variety of services to help shippers improve their supply chains.

Applying tech and engineering in logistics

After completing an initial review of FORTPRO’s warehouse, UPS made recommendations that not only helped the master distributor eliminate the blocked aisles and free up storage capacity, but also made room for twice the inventory that the company was previously carrying.

“We doubled our inventory value by rearranging the pallet positions in our warehouse,” Romero explains. “Because of this, we’ve been able to keep growing our inventory and our revenues without having to move out of our current facility.”

By separating its pallet storage area from its picking area, FORTPRO was able to improve throughput, increase efficiency and store more inventory in its warehouse. This translated into more sales and higher revenues.

“We had a fulfillment rate of about 75% and we’ve since increased that to 90%,” says Romero. “We were losing sales because we didn’t have enough space for inventory, and now we’re able to fulfill those orders.”

Perfect time to partner

According to Romero, the partnership with UPS came along at the perfect time. “We were looking for a bigger warehouse, and they showed up and offered their services,” he explains. “We reviewed their plan and it was a no-brainer. We went ahead and contracted with them and the decision paid for itself within a year. We’re very happy with the outcome of that investment.”

Romero particularly liked UPS’s approach, which started with a complete site survey and included a full report on which areas the company was struggling with and why. The provider then outlined all of its recommendations and potential solutions. “They spent a couple of weeks here working in our warehouse, talking to our team members and detailing all of the issues that we were experiencing in our facility,” he says. “Then, they came back with a plan for addressing all of those issues.”

The plan included detailed recommendations about product flow in the warehouse, storage rack positioning and ways to improve facility-wide organization. FORTPRO didn’t waste any time implementing the solutions. “We took action very quickly. We changed the layout, tore out office space and changed the layout of all of the racks in our facility,” Romero explains.

Using a velocity analysis, UPS developed a heat map to show where the products were located and how they were being slotted incorrectly. The company then provided recommendations for better product storage and flow.

Today, the fastest-moving items are placed closest to its packing area. As a result, those items are very close to employees who can pick the parts quickly, put those parts in the packing area and get them out the door to end customers faster than ever.

Better utilization of existing space

To date, FORTPRO has implemented about 90% of UPS Customer Solutions’ recommendations. The changes—most of which took place within the first six months of working with UPS—have had a significant impact on the master distributor’s operation.

In fact, inventory capacity has doubled and revenues have increased by about 25% from 2021 to 2022. The company also has better organized and improved density of product positioning; it has increased physical capacity thanks to facility layout redesign; and can now accommodate roughly 10% more pallet positions within its existing physical footprint.

Through its collaborative relationship, FORTPRO has also been able to increase its order-staging capacity in a way that’s reduced both floor congestion and excess travel. The company has cut down on errors, improved inventory visibility, reduced inventory exceptions and is no longer challenged by process delays due to excess travel and search delays. Other changes that FORTPRO made include the implementation of velocity slotting and the application of progressive cycle counting practices.

Using those progressive cycle counting practices, the company can now quickly review inventory positions; double-check that everything is in the right location; determine whether any items are missing; and make adjustments based on that data. “UPS also recommended that we start using inventory counting practices,” says Romero. “We also made that change and are now adjusting our inventory based on that practice.”

Information at their fingertips

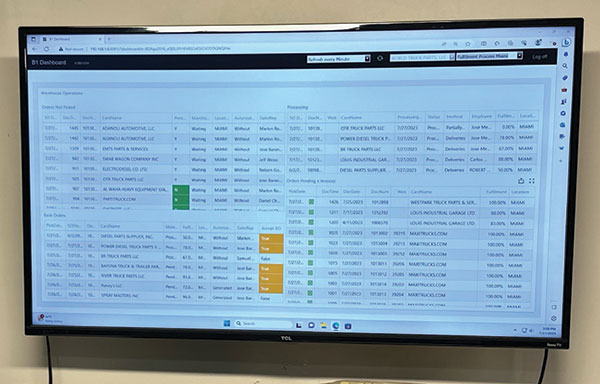

As FORTPRO implemented UPS’s plan and the related solutions, the master distributor also gained access to analytics dashboards that it didn’t have before. Warehouse managers now have all of the order, process, picking and packing information right at their fingertips. They can view the key performance indicators (KPIs) for all associates and make good decisions based on the accurate data that’s collected via scanner.

“Employees are more motivated because they get reports showing how they’re doing and the improvements that they’re making,” says Romero. “Our whole staff has access to those dashboards—everything is connected.”

For example, the warehouse manager dashboards display all of the processes taking place within the warehouse. Those dashboards show when the order is released to the warehouse, when it’s being picked, when it goes from picking to packing, when it’s 100% packed and whether the order has been invoiced and/or paid for. The company also installed two large screens that employees use to track order progress and other details.

The company’s sales and customer service teams have also benefitted from FORTPRO’s dashboards, which provide real-time information about individual orders. “These tools support good communication with our customers and ultimately lead to customer service improvements,” says Romero. “The KPIs also help managers stay informed about individual employee productivity and the productivity of our operation as a whole.”

Fulfilling orders faster and more accurately

By separating its picking and packing operations, FORTPRO has reduced the time it takes to fulfill orders and get them out the door.

Previously, the employee who picked the order also packed it for shipping. This left full control to a single individual who didn’t have a “second set of eyes” double checking the work.

By separating out those two fulfillment activities, the company is able to pick orders faster and has the checks and balances in place to ensure higher levels of accuracy on every order.

“We doubled our inventory value by rearranging the pallet positions in our warehouse…We had a fulfillment rate of about 75% and we’ve since increased that to 90%.” - Marlon Romero, FORTPRO USA/World Truck Parts LLC

“We were dealing with mistakes because there were no ‘double controls’ in place,” Romero points out. By dividing up the work, we’re picking faster and with more accuracy.” And because the packing employees have no picking responsibilities, they quickly identify and filter mistakes—which means way fewer “wrong parts” send out the door to customers.

“UPS designed a packing area for us that we didn’t previously have,” says Romero. “The end result is a dedicated space in the warehouse where workers can pack and double-check order accuracy much more efficiently.” These wins helped FORTPRO achieve that 25% increase in revenues while at the same time growing its net profits by 90%.

“When you go far beyond the break-even of the company, everything else is just additional profit. That’s what we experienced in 2022,” says Romero, who adds that those increases wouldn’t have been reachable had FORTPRO been forced to invest in more, high-priced real estate. “If we moved to another facility, that net profit growth wouldn’t have occurred because there would have been more operational expenses. But staying in the same location and increasing 25% in sales boosted the net profit of the company.”

Looking ahead, Romero says FORTPRO plans to increase the size of its Houston facility and work with UPS Customer Solutions to optimize that warehouse space even before the company officially occupies the new space. “Sales growth is substantial in Texas right now,” says Romero. “To address that growth, we’ll be building a plan ahead of time and working with UPS to create a move-in ready facility.”

Article Topics

3PL News & Resources

GXO’s acquisition of Wincanton is a done deal LM Podcast Series: Assessing the freight transportation and logistics markets with Tom Nightingale, AFS Logistics Going Deep with 3PLs Orchestration: The Future of Supply Chain LM Podcast Series: 3PL market update with Evan Armstrong GXO’s acquisition of Wincanton remains on track for completion by late April New TIA Q4 Market Report sees declines amid some positive trends More 3PLLatest in Logistics

Port Tracker report is bullish on import growth over the balance of 2024 Varying opinions on the tracks regarding STB’s adopted reciprocal switching rule National diesel average falls for the fourth consecutive week, reports EIA New Descartes’ study examines consumer preferences, changes, and shifts in e-commerce home delivery preferences Potential Canadian rail strike could damage the country’s economy C.H. Robinson highlights progress of its AI-focused offerings with a focus on automating shipping processes UPS announces CFO Newman to leave company, effective June 1 More LogisticsAbout the Author

Subscribe to Logistics Management Magazine

Find out what the world's most innovative companies are doing to improve productivity in their plants and distribution centers.

Start your FREE subscription today.

May 2024 Logistics Management

Latest Resources